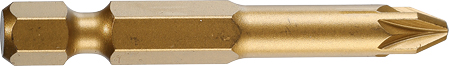

Bit 1/4" E 6,3 - PZ

TORSION - TiN CVD full coated

| Size | Length | bulk | SU | Colour Bag | PU | SU | SYS Box | PU | SU |

|---|---|---|---|---|---|---|---|---|---|

| PZ 1 | 50 mm | 03015 | 50 | 02730 | 5 | 6 | 02415 | 5 | 6 |

| PZ 2 | 50 mm | 03016 | 50 | 02731 | 5 | 6 | 02416 | 5 | 6 |

| PZ 3 | 50 mm | 03017 | 50 | 02732 | 5 | 6 | 02417 | 5 | 6 |

PU = packaging unit

What means...?

milled

milled

milled

- for screw connections requiring perfect fit

- clamping effect in the screw

- sharp edges

- for screwing operations with normal torque

- engaging in material structure

- cutting

- also reasonable for small quantities

- high fitting accuracy

TiN CVD

TiN CVD

TiN-coated

Titanium nitride for hard bits ensuring

- longer service life

- an increased wear protection

- that the surface is about 50% harder than that of bits provided with normal coating

CVD coating - full

The CVD bits are fully coated using a high-temperature method with a temperature of about 780°C. A very strong bonding between the coating and the bits is thereby established.

- coating hardness approx. 95 HRc

- higher torque values

- longer service life than PVD coating

- perfect wear protection

TORSION

TORSION

TORSION

- each standard bit has a very short TORSION zone

- bits featuring an extended, i.e. longer TORSION zone are more flexible

- users are able to stop applying force when screwing before the bit breaks

- in case of torsion up to a certain degree, the TORSION zone returns to its previous initial position

- TORSION bits break later and resist higher loads

- they are perfectly suitable for hard screwing operations

- longer service life

- product less expensive thanks to longer service life